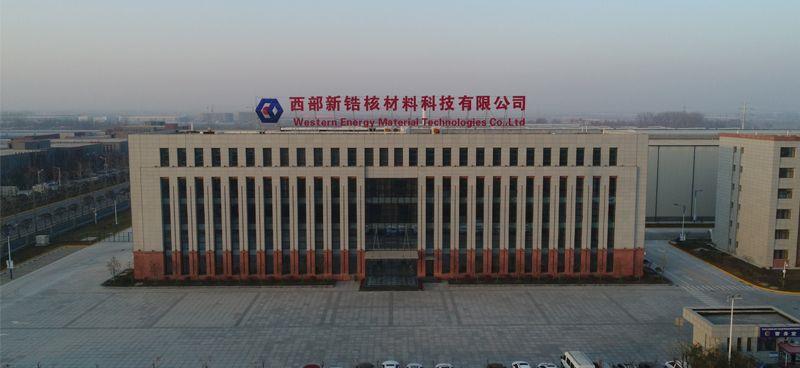

Western Energy Material Technologies Co., Ltd. (WEM) is located in Xi'an Economic and Technological Development Zone, which is founded in April 2013. The registered capital is 230 million yuan, the total investment of the project is 1.1 billion yuan, covering an area of more than 300 mu. CNEIC is the first largest shareholder of WEM, accounting for 34.78% of the registered capital of the WEM. The second largest shareholder is Northwest Nonferrous Metals Research Institute, accounting for 33.91% of the registered capital of WEM. Other shareholders are Xi'an Industrial Investment Group Co., Ltd., CITIC metals Co., Ltd. and natural person shareholders.

According to the modern enterprise management mode, the organization is composed of seven departments, one office, four factories and analysis and testing laboratory, with 247 employees, including 7 professors, 5 doctors and 48 masters. WEM has established a first-class technology R & D team, a high-level professional skill team, and a strong executive management team, and has been awarded the key innovation research team of Shaanxi Province and the innovation talent experimental base of Shaanxi Province. In 2015, it was awarded the title of high-tech enterprise, won the Xi'an talent work innovation base in 2017, won the provincial and municipal level II postdoctoral innovation base in 2018, and won the Xi'an skilled talent recruitment and talent introduction workstation. In January 2019, it was approved to establish academician and expert workstation, and vigorously cooperated with northwest non ferrous Metal Research Institute, Chongqing University and Shanghai University to establish "production, learning and research" alliance.

WEM aims to build an independent scientific research and production base for nuclear zirconium and hafnium materials, and build a world-class innovation platform integrating R&D, evaluation, performance analysis, testing, pilot test and industrial production of national special nuclear metal materials. The main products are zirconium, titanium and other rare metal alloy pipes, rods, plates and strips. The nuclear grade zirconium is mainly used for the core materials of "HUALONG 1" independent nuclear power reactor. It is applied to the zirconium alloy pipes (cladding pipes, guide pipes, instrument pipes, etc.), bars, plates and strips, etc. for nuclear fuel assemblies, as well as the zirconium alloy pipes, bars, plates and strips, and different sections for nuclear applications. At the same time, it can be used in the petroleum and chemical industries(Organic acid, acetic acid, nitric acid, sulfuric acid manufacturing, etc.), spent fuel reprocessing to provide high-quality industrial zirconium materials, and some hafnium alloy materials. In addition, WEM's extruder, plate mill and other equipment capacity surplus and high-precision characteristics of the equipment, to carry out processing business. WEM has smelting, billet and tube rods, plate production line, a total of more than 300 sets, complete sets of equipment, smelting production line with the international advanced vacuum since the electricity arc furnace 14 sets of major equipment such as billet production line has the international first-class 45 mn horizontal double acting type extrusion machine and so on the main device 17 sets of tube rod production line with the international top KPW series high-speed cold rolled pipe unit 24 sets of major equipment such as plank production line has the international leading four high reversible plate strip cold rolling unit 11 sets of major equipment such as analytical testing laboratory with the international newest type main equipment such as the composition of the detector 42 sets.

With the goal of establishing a complete and independent nuclear zirconium alloy industry system, WEM has always maintained its leading R&D and manufacturing capacity in China, comprehensively mastered the core technology of zirconium alloy materials, implemented the "application generation, development generation, pre research generation" of nuclear zirconium alloy, continuously promoted the R&D and application of its own brand zirconium alloy materials, and made greater contribution to building a nuclear power.